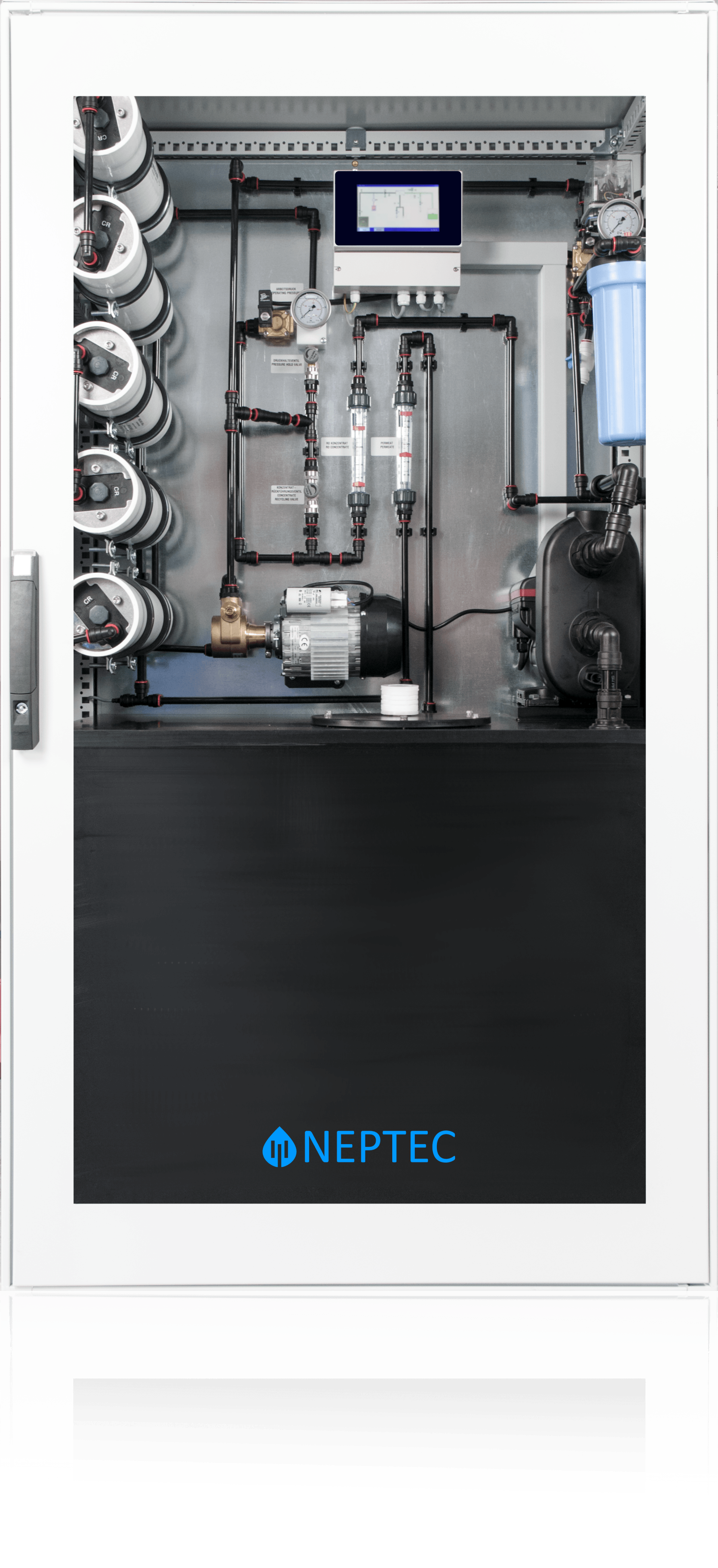

RO beta

TYPE II ∙ 500 - 1100l/h

The Reliable Ultrapure Water Supply for Entire Buildings

Our RO beta is modular-designed, providing high flexibility to adapt to your specific needs from 500 to 1100L/h.

All components are mounted on a space-saving frame.

Designed for a maximum service life and operational safety.

RO beta systems are built with highest quality components to provide the maximum water quality while maintaining latest industrial standards.

Innovative

User Interface

Intelligent Features

Supporting

Documentation

Related Products